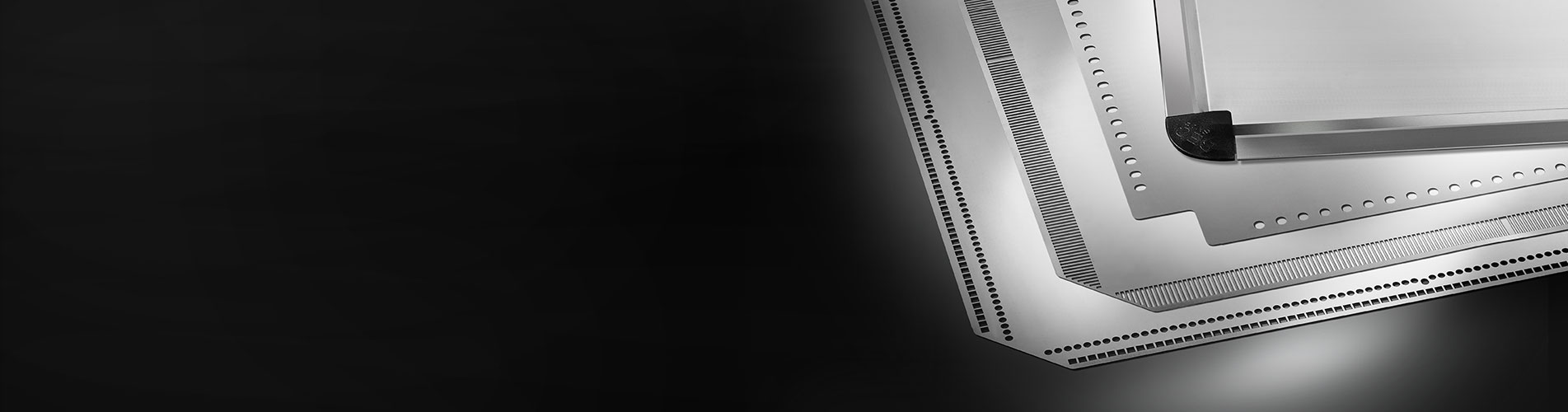

VectorGuard

Standard oder High Tension

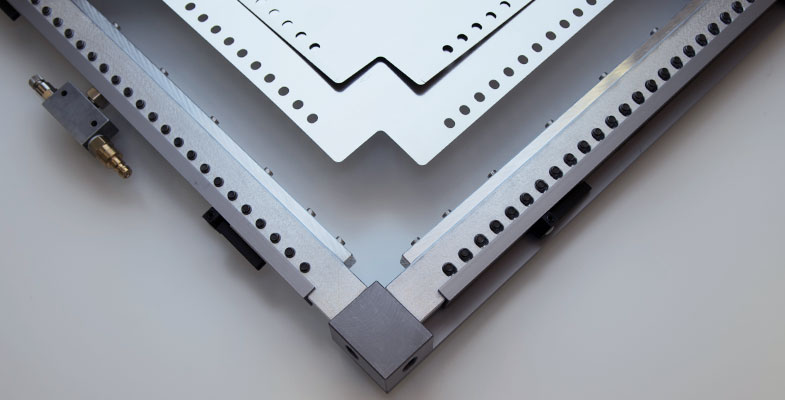

This four-sided spring-tensioning system accommodates the VectorGuard stencil surrounded by aluminium borders. Easy handling, as well as increased stability of the stencil thanks to an aluminium profile, characterise the system:

- VG260 23" x 23"

External dimensions: 584 mm x 584 mm

Adaptable to: 736 mm x 736 mm

Stencil size: 555 mm x 555 mm - VG265 29" x 23"

External dimensions: 736 mm x 584 mm

Adapable to: 736 mm x 736 mm

Stencil size: 709 mm x 555 mm

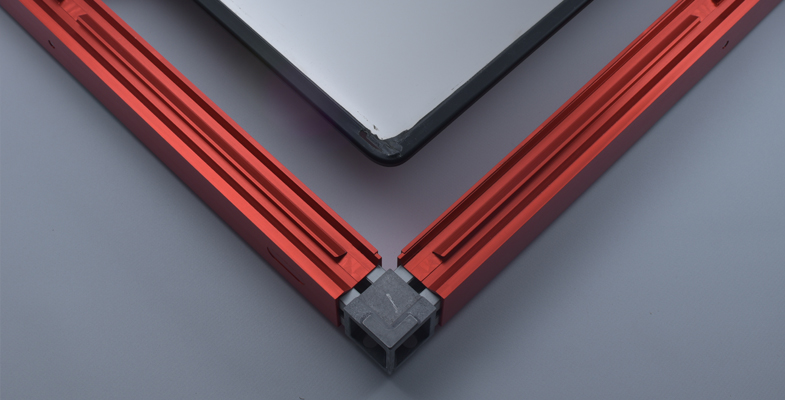

ALPHA tensoRED

New four-sided tensioning system, which tensions Tetrabond and VectorGuard stencils with up to 45 N/cm². The tensioning system works purely mechanically without compressed air. To tension the stencil, a charging station is needed.

- 23" x 23" Master Frame

External dimension: 584 mm x 584 mm

Stencil size: 555 mm x 555 mm

- 29" x 23" Master Frame

External dimension: 736 mm x 584 mm

Stencil size: 709 mm x 555 mm

Master Frames are adaptable to 736 x 736 mm²

Quattro-Flex II-3

This four-sided quick-tensioning system holds the license-free stencil tensioned by means of compressed air. Pressure reducers allow for continuous and precise control of the stencil tensioning:

- Square

External dimension: 584 mm x 566 mm

Adaptable to: 736 mm x 736 mm

Stencil size: 555,5 mm x 555,5 mm

- Rectangular

External dimension: 720 mm x 584 mm

Adaptable to: 736 mm x 736 mm

Stencil size: 709,5 mm x 555,5 mm

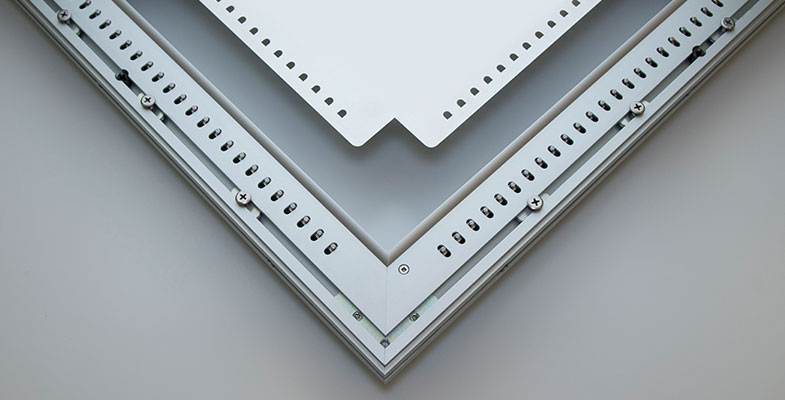

Quattro-Flex-3

The new system is used with a loading station, without hold-down borders. The loading station can be dispensed with when using BECsnap stencils for QuattroFlex. The frame is slightly lighter than its predecessor and offers a 5-mm larger squeegee blade area circumferentially:

- Square

External dimensions: 584 mm x 566 mm

Adapable to: 736 mm x 736 mm

Stencil size 555,5 mm x 555,5 mm

- Rectangular

External dimensions: 720 mm x 584 mm

Adapable to: 736 mm x 736 mm

Stencil size: 709,5 mm x 555,5 mm

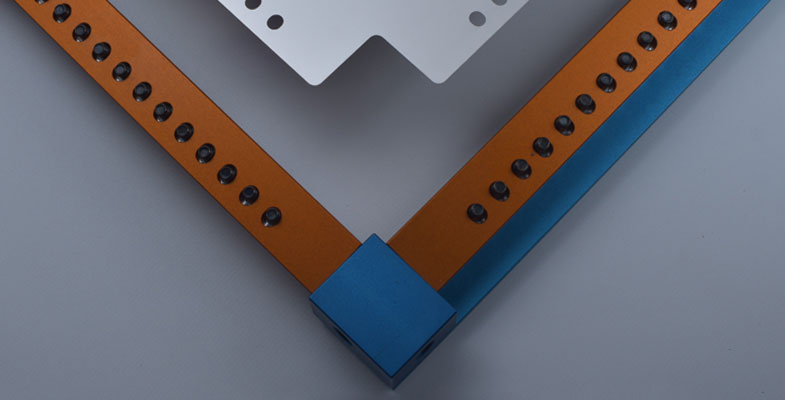

AlphaTetra

The four-sided spring tensioning system is suitable for stencils

with AlphaTetra, MicroMount or the patented BEC100 edge perforation:

- 23" x 23"

External dimensions: 584 mm x 584 mm

Adaptable to: 736 mm x 736 mm

Stencil size: 558 mm x 558 mm

- 29" x 23"

External dimensions: 736 mm x 584 mm

Adaptable to: 736 mm x 736 mm

Stencil size: 711 mm x 558 mm

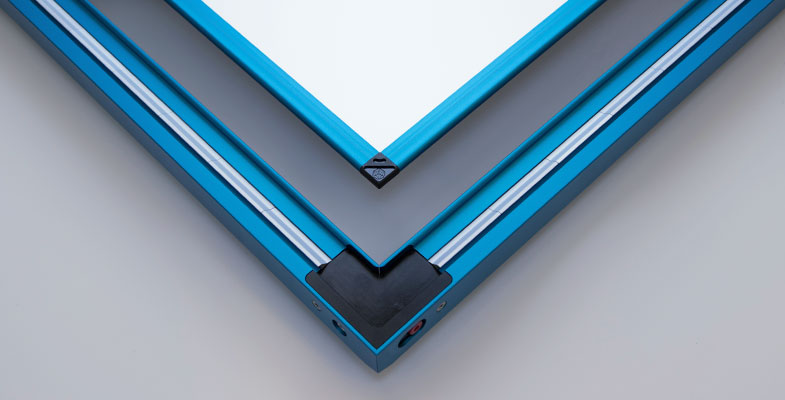

ZelFlex Z4P

This four-sided quick-tensioning system uses compressed air to tension the license-free stencil. A permanent supply of compressed air is not necessary for this; the compressed air supply can be removed immediately after tensioning the stencil:

- Small

External dimensions: 558 mm x 558 mm

Stencil size: 520 mm x 520 mm

- Standard

External dimensions: 584 mm x 584 mm

Stencil size: 546 mm x 546 mm

- Large

External dimensions: 736 mm x 736 mm

Stencil size: 698 mm x 598 mm

Reliable quick-tensioning frames for SMT stencils

Achieve highly accurate results with quick-tensioning systems

Quick-tensioning frames ensure a good and evenly fixation of the SMD stencil. Efficiency, precise printing results and comprehensive process reliability are particulary important. The stencil is ready for use quickly and can be archived space saving easily. We offer quick-tesnioning frames of differtn types such as VectorGuard, Quattroflex, ZelFlex and AlphaTetra. You benefit from the latest technologies in tensioning frame technology, always up to date.

VectorGuard

VectorGuard quick tension frames are a common solution for industrial stencil printing. The proven spring system guarantees consistent tensioning as well as changeover with ease. It is offered in two versions. The classic VectorGuard frame, cost-efficient and versatile in its use, is the proven companion for SMT processes. The VectorGuard High Tension, on the other hand, offers up to 65% higher tension, which favours a more even release of the stencil from the substrate and enables increased transfer efficiency of the solder paste.

Quattro-Flex

The Quattro-Flex quick-tensioning system is a maintenance-free frame that is operated with compressed air thus keeping the stencil permanently under tension. A compressed air connection in the paste printer is mandatory to ensure reliable stability of the stencils over a longer period of time. The latest generation of Quattro-Flex frames can be used with or without a charging station and offer space-saving, reliable and safe handling.

ZelFlex

The pneumatic ZelFlex tensioning frames score points for their handling with proven technology. The integrated compressed air reservoir keeps the stencil constantly tensioned for up to 24 hours. After fixing the stencil in the frame, the compressed air source is removed and is no longer required during the printing process.

AlpaTetra

In the four-sided AlphaTetra quick-tensioning frame, the stencil is held under tension by the mechanical spring clamping system and released on a pneumatic basis. Becktronic manufactures the matching stencils with the patented edge perforation BEC100, which is also available with edge protection as an option.

Alpha tensoRed

The Alpha tensoRed is similar to the VectorGuard frame, but without internal air tubes. This requires a mechanical loading station for inserting and removing the stencil from the frame.

Of course, BECKTRONIC manufacture SMD stencils for all standard quick-tensioninge frames - whether Quattro-Flex or VectorGuard, ZelFlex, AlphaTetra, Heeb, Metz or Paggen. Our stencil type BECsnap is a good choice for use in Quattro-Flex or VectorGuard frames.

We offer expert and independent advice. Together with you, we will find the optimal solution when choosing a quick-tensioning frame for your electronics production.

Still have questions?

Contact person

+49 2743 9204 - 15

Monday through Friday, 8 - 17 hrs

Contact form

BECnews

Subscribe now to the Becktronic newsletter for the latest industry information, news from our company, and tips and trends concerning laser-cut SMD stencils and high-precision stencils for LTCC, wafer and special applications!